SKID WATER TREATMENT PACKAGES

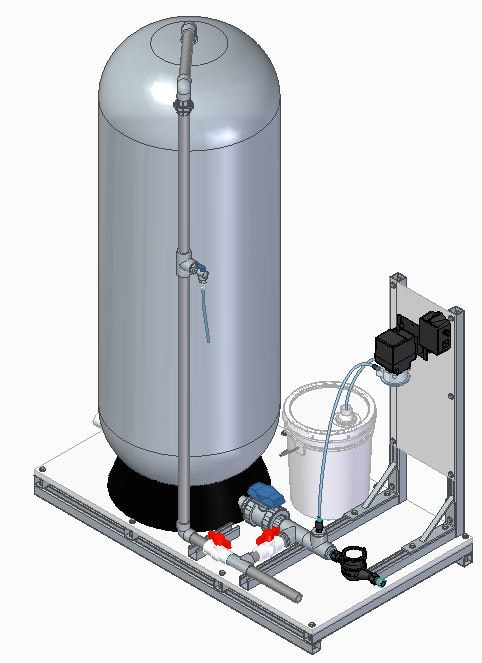

DISINFECTION CONTACT SKID

Disinfection contact skids are sized in order to achieve the minimum disinfection contact time to achieve log reduction credits as per the local regulatory body. All equipment is mounted to a lightweight skid that can be lifted with a forklift or pallet jack. The system are design to fit standard commercial door openings when possible. Systems include the following:

- chemical injection pump

- chemical injection controller

- pulsed water meter/totalizer

- mixing/baffle tank(s)

- bypass and isolation valves

- water quality sample valves

SURFACE WATER CYST REMOVAL/INACTIVATION

Surface water cyst removal/inactivaton skids provide a dual barrier for cysts mounted to a lightweight skid. Skid materials are waterproof, mold resistant, and do not absorb water. See the specifications below:

- 1 micron absolute LT2 rated housing and cartridge

- NSF-55 Class A UV disinfection up to 60 gpm

- 186 mj/cm2 option available for use as primary disinfection

- UV dose monitoring and data logging

- required turbidity below 1 NTU and UVT above 75%

- Includes bypass and isolation valves

- water quality sampling valve

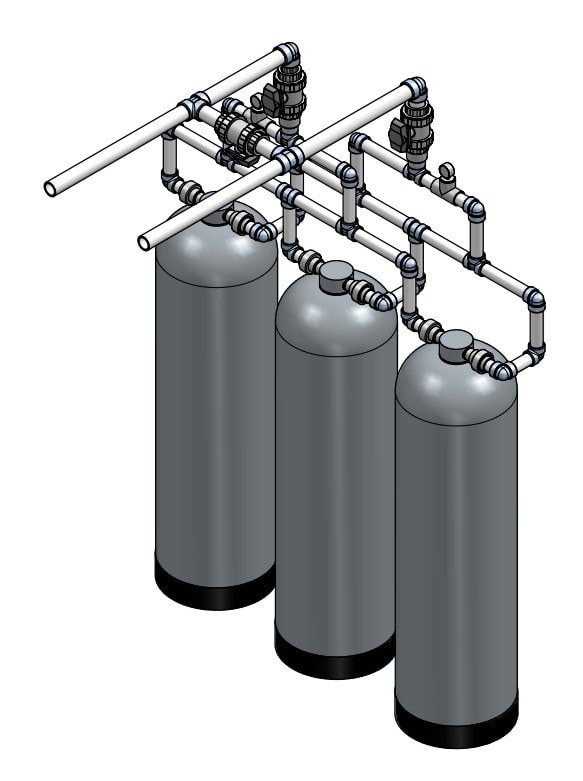

COAGULANT CONTACT SYSTEM

Coagulants require vigorous mixing followed by contact time in order to form a proper floc that can be filtered out in following treatment steps. The system below has the following features:

- Fiberglass reinforced tanks

- Simple in/out heads that require no external control

- Service unions built into the manifolds for easy installation and service

- Pressure gauges to monitor pressure drop through the system

- True union bypass and isolation valves

- Schedule 80 PVC plumbing

- Manifold designed with equal length runners to encourage equal flow distribution

- Reverse Flow Risers to ensure mixing and to prevent short circuiting inside the contact tank

- Used in conjunction with the Dyna-Pro Static Mixer for optimum performance